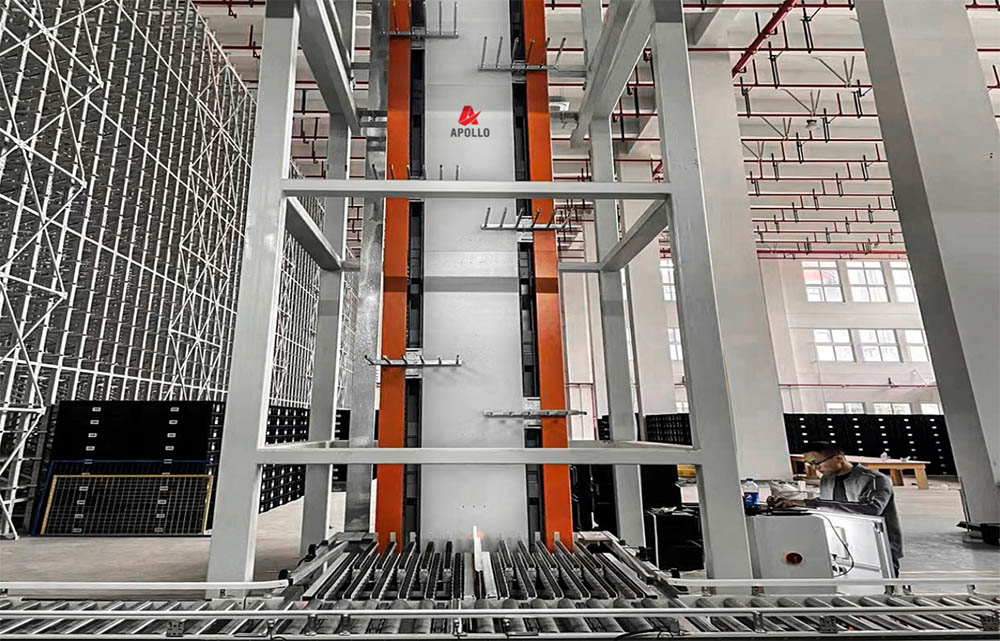

Rotative Vertical Sorter for multi-layers sorting in vertical direction

Industry Applications

Vertical Rotative Sorter is right solution to solve the problem of multiple exits sorting in vertical direction. It can be used to sort, buffer and sequence small to medium size trays or boxes. The multi-level fully automated sequencing operation allows drastic footprint optimisation.

● Multiple functions: for lifting, for sorting

● Small space occupation, small cutting of floor hole

● Various forms for inlet and outlet of goods

● Throughput: 600-1000 products/hour (according to the size of goods, inlet and outlet forms, etc.)

● Products to be handled: cartons, plastic boxes, trays, small wooden cases, woven bags, bottles, tires and other packaged products

Lift goods through high precision and high strength fork

Main frame column adopts high strength steel plate bending molding

The fork platform uses high strength square tube refining production

Equip with high precision chain walking wheel

The modular and standardized design can combine with most of the customer's conveyor lines

APOLLO uses a unique mechanism to solve the vertical direction of continuous sorting. Combined with our DWS control system, it can be accurately sorted to multi-layer exits. APOLLO Rotative Vertical Sorter is extremely small footprint, this lifter can fit into almost any layout. The compact unit is very easy to incorporate into your transport system, conveyor at entry or exit can be equipped together for continuous conveying, like roller conveyor, belt conveyor, traverse movement type, turnover type and lifting type etc.

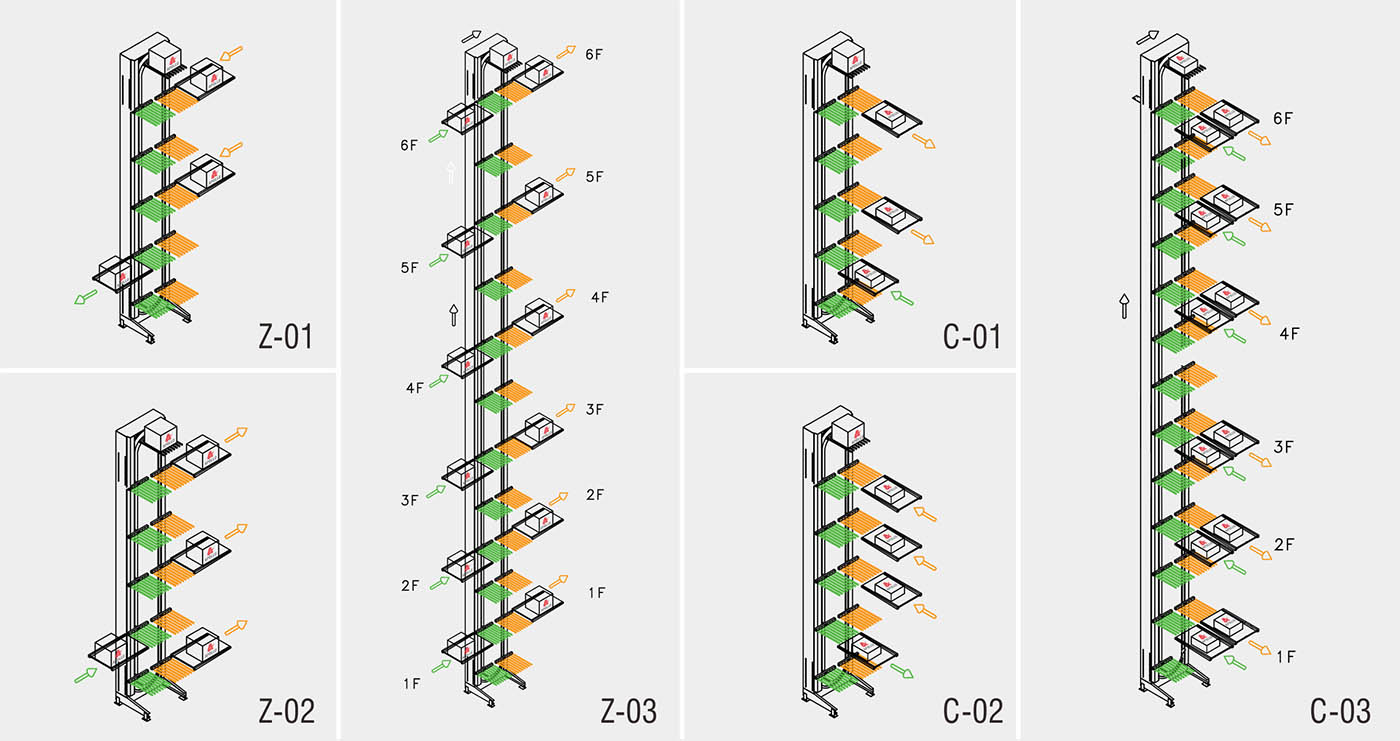

When add retractable conveyors to the lifter column, this makes products entering or discharging at any floor level while still just using one vertical movement. APOLLO Rotative Vertical Sorter has 2 types according to different direction for entry and exit of products, Z type and C type, Multiple Entry Multiple Exit, One Entry Multiple Exit, Multiple Entry One Exit etc.

| Vertical Sorter Data | |

| Sorting throughput | 600-1000 products/hour (Up to the goods size and form of extry and exit) |

| Lifting height | 3-35m |

| Capacity | ≤ 50 kg |

| Goods size | ≤L600×W400×H400 mm (Standard type) ≤L800×W600×H400 mm(Heavy-duty type) |

| Goods type | Carton, turnover box, gallon, case, bag etc. |

| Sorting mode | Multiple entry multiple exit, one ertry multiple exit, multiple entry one exit |

Frequently Asked Questions:

Our innovation is at your service

Consumer behavior has changed, supply chains have not. Let's talk today to find perfect design and make your sorting more easy, more safe, more efficiency.